Our Projects and Prototypes

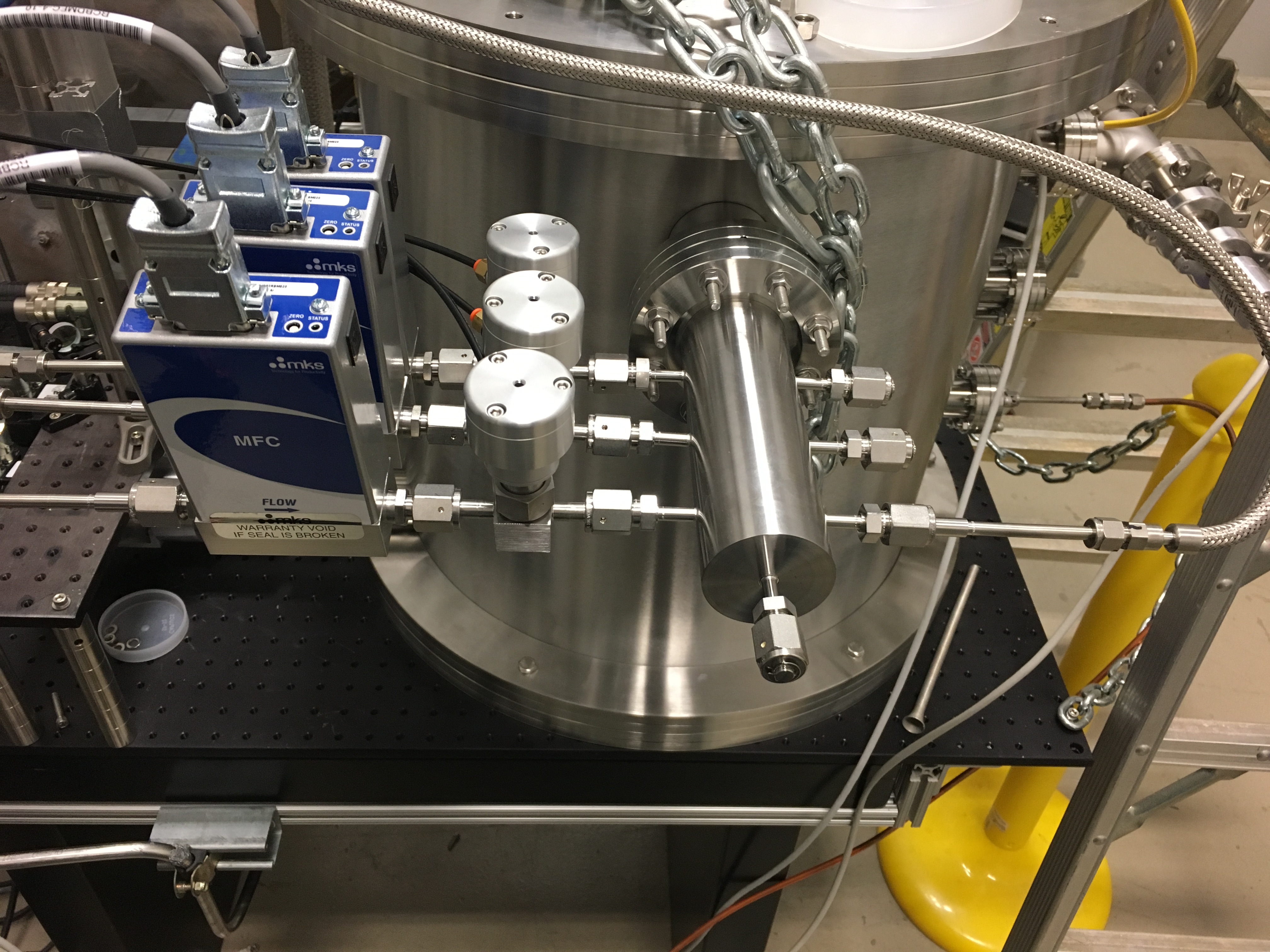

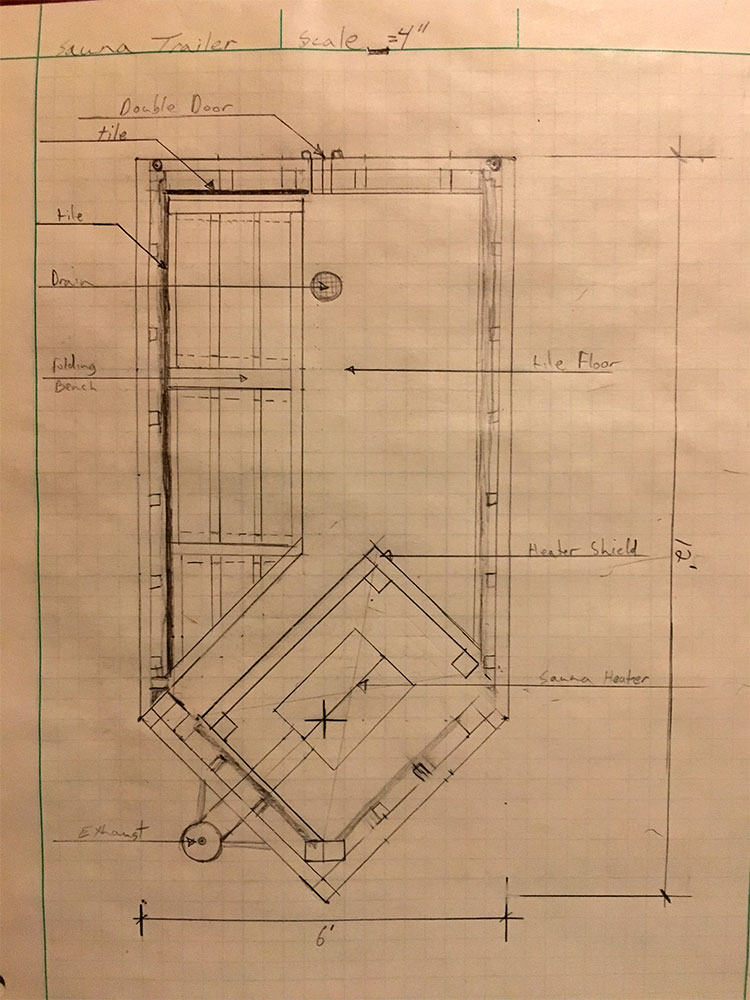

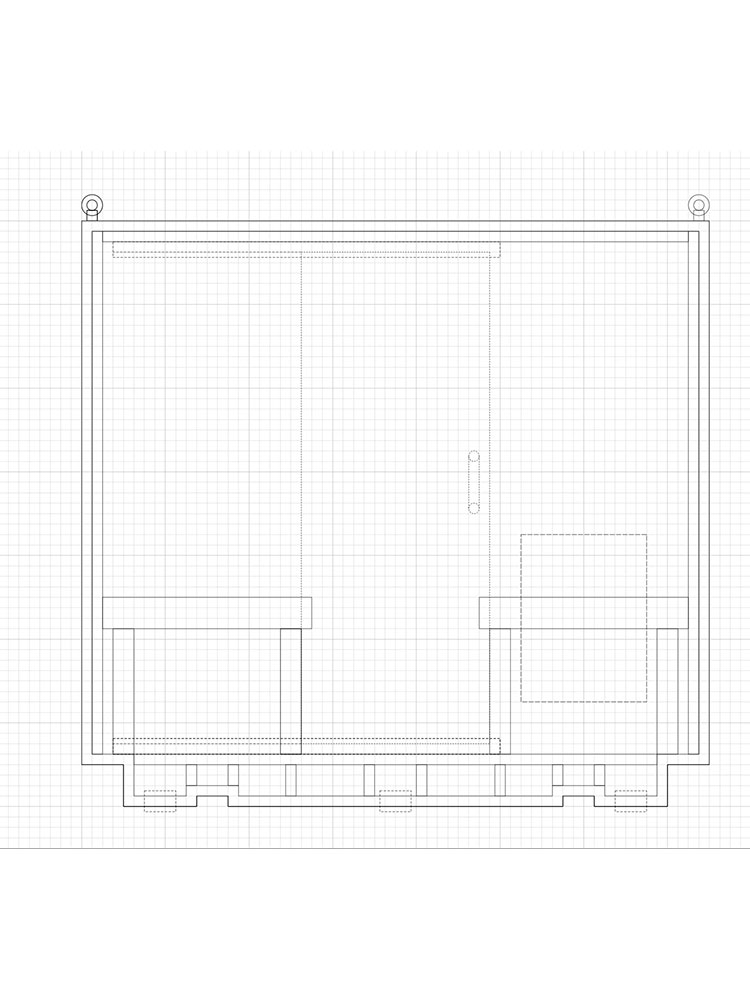

Ceramic Additive Manufacturing

Selective Area Laser Deposition, Additive manufacturing of ceramic materials. A series of reactive gas precursors are metered into a vacuum chamber. Gas pressure and flow rate are computer controlled. Powder bed handling inside of the vacuum chamber creates layers of ceramic or diamond powder. A laser scans a pattern onto the powder, heating the surrounding gas to reaction temperature. Gas diffuses in and solidifies the powder into solid ceramic. Layer of fresh powder and repeat, and you have 3D printed ceramic. Temperature feedback is accomplished through infrared thermography; laser power tied to temperature reading to control reaction conditions. Several safety features are included, automatic gas shut off and leak sensing, laser interlocks and emergency shut offs.

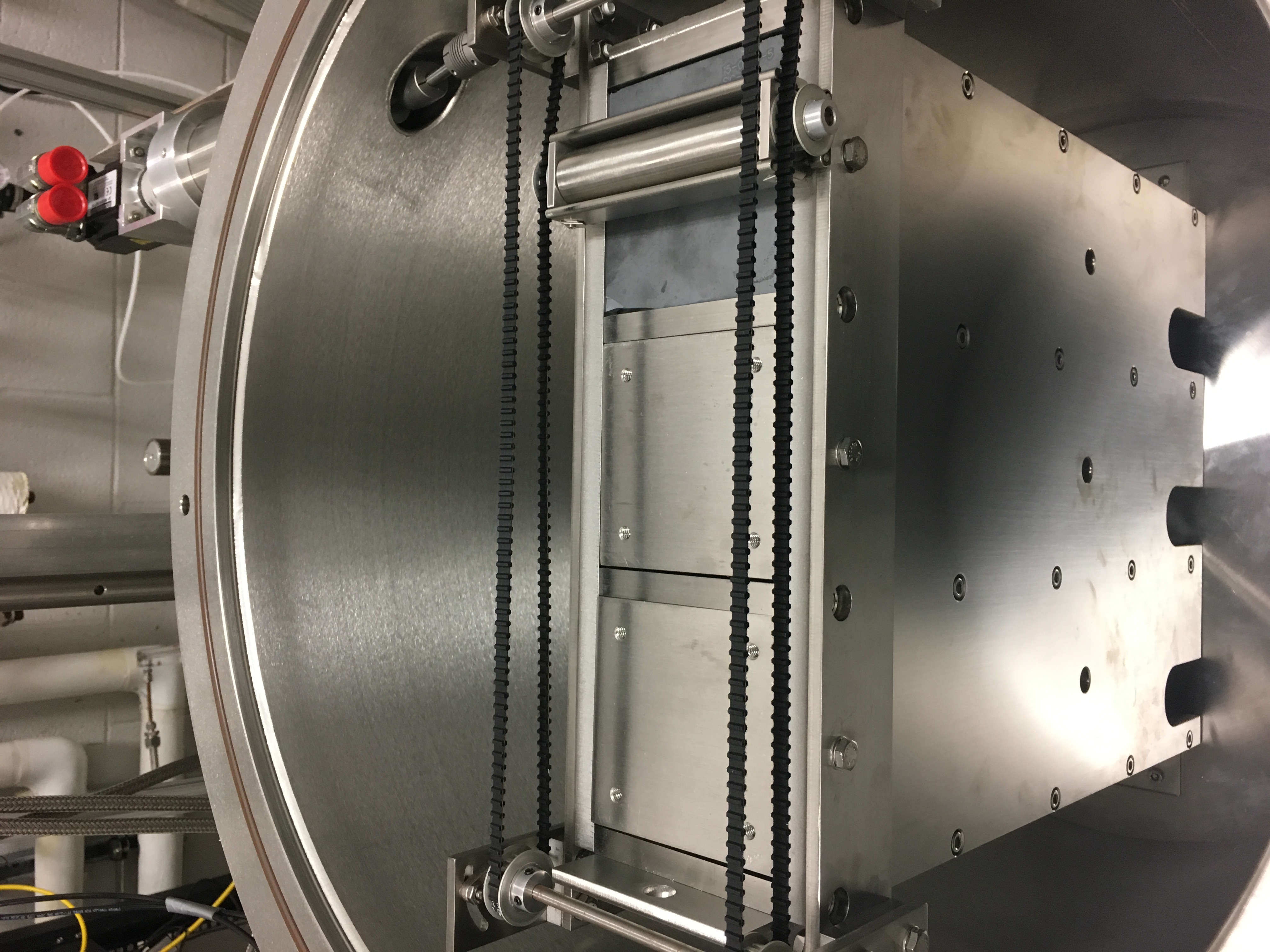

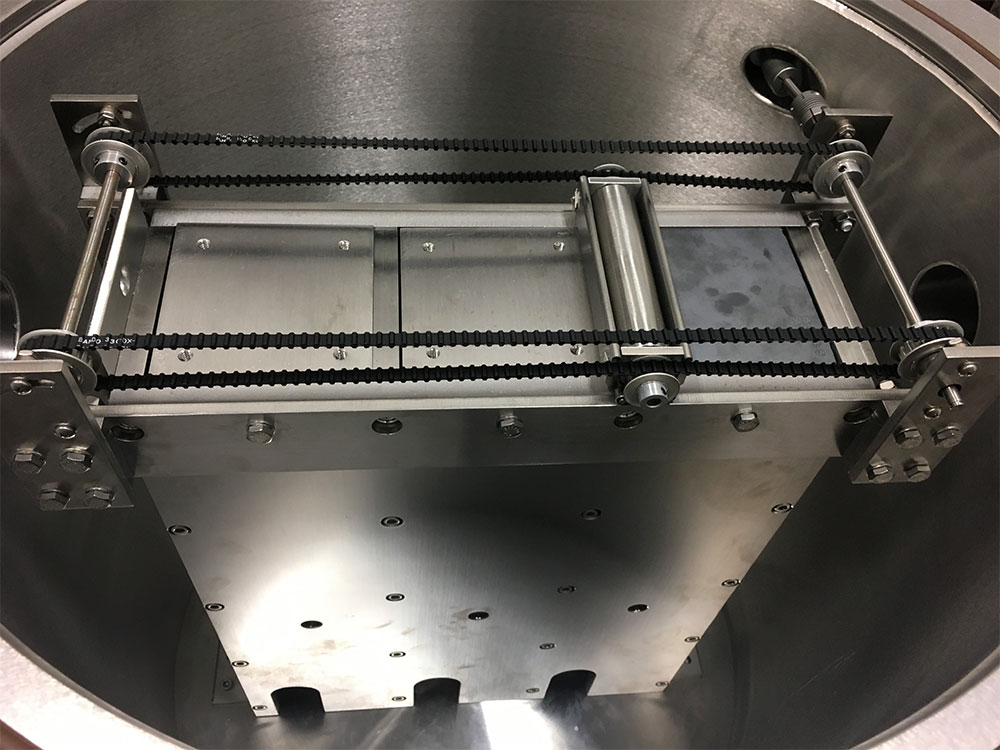

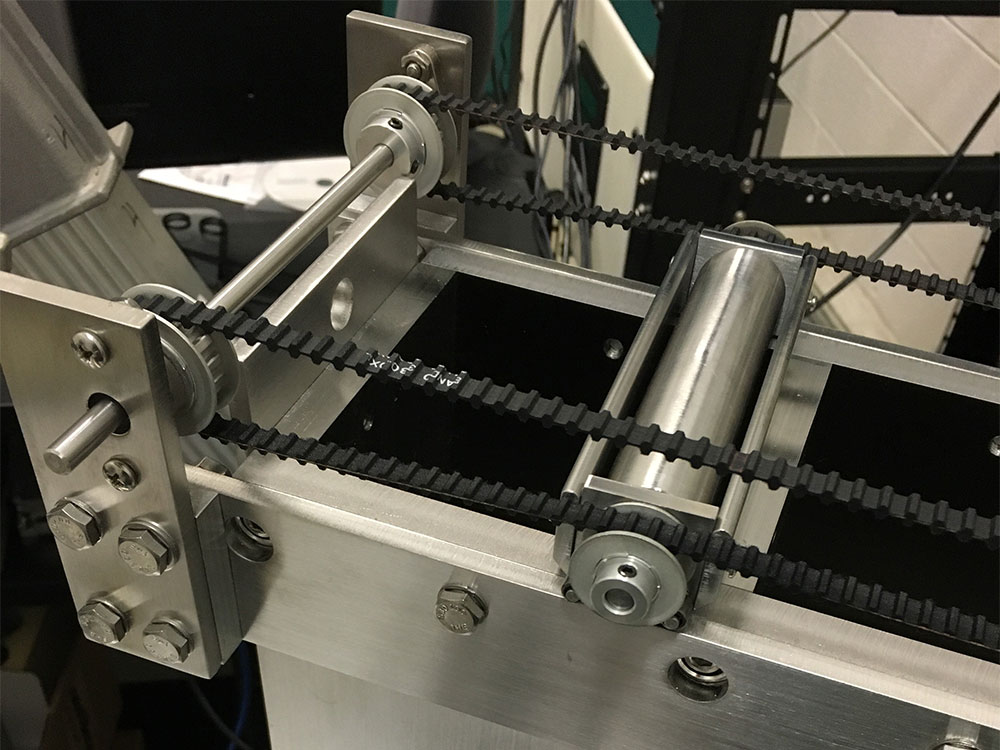

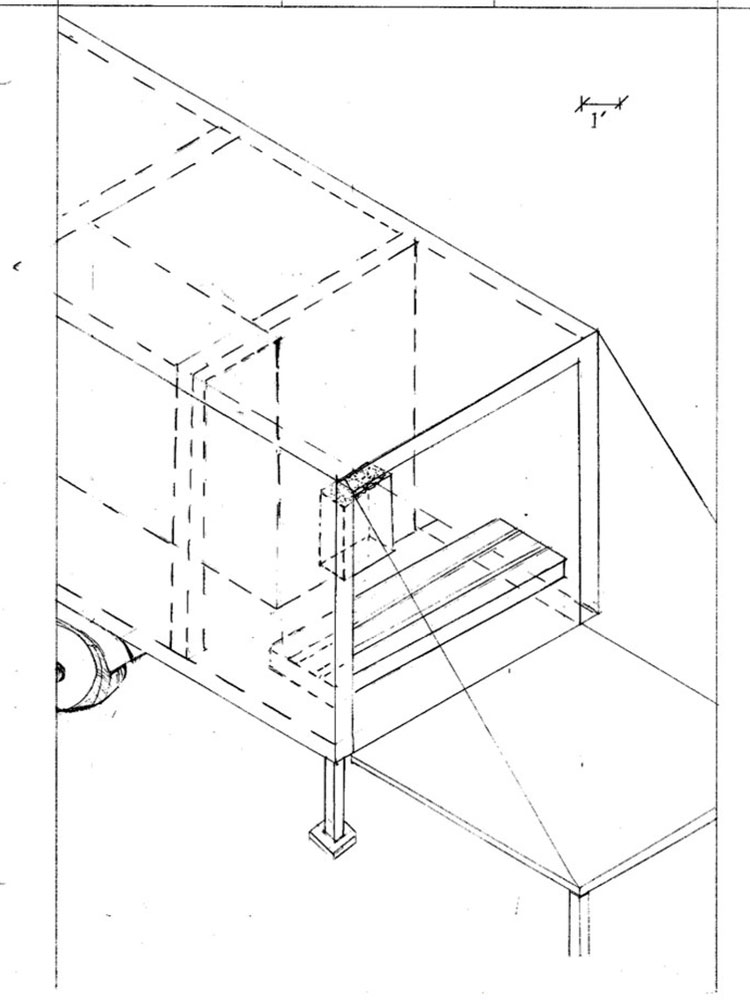

Powder Handling

Powder handling for additive manufacturing of the powder solidification type of 3D printing. Work piece powder bed in the center and the possibility of two different powders to be applied layer by layer. Each layer of powder fusing into shape by a laser deposition process. Powder roller and doctor blade for smoothing powder layers between deposition runs.

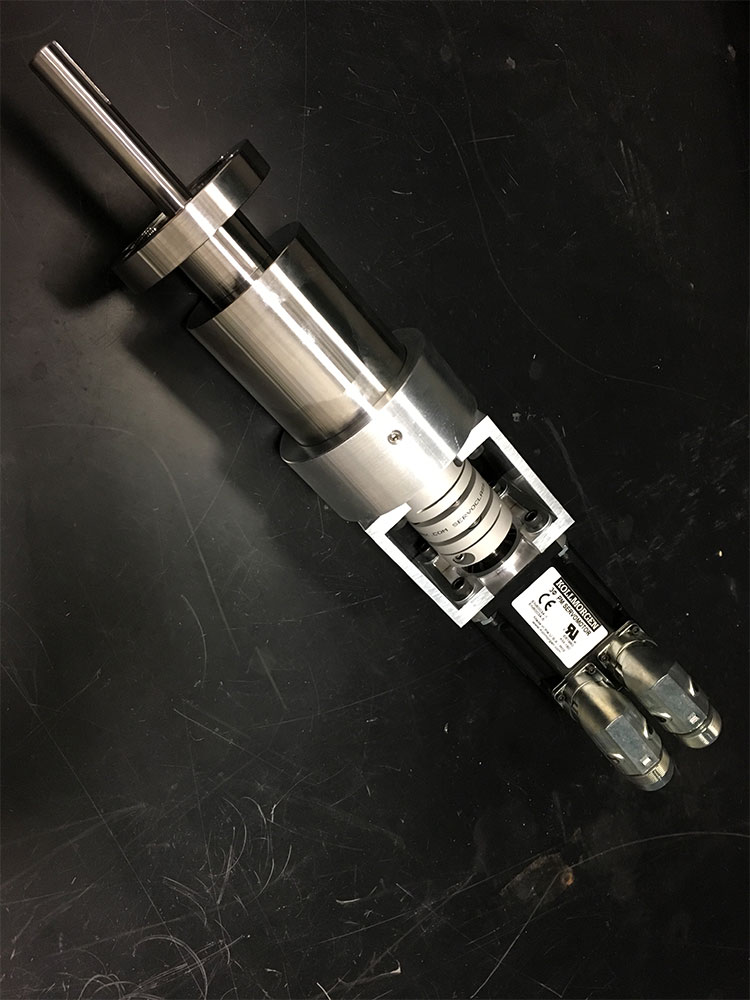

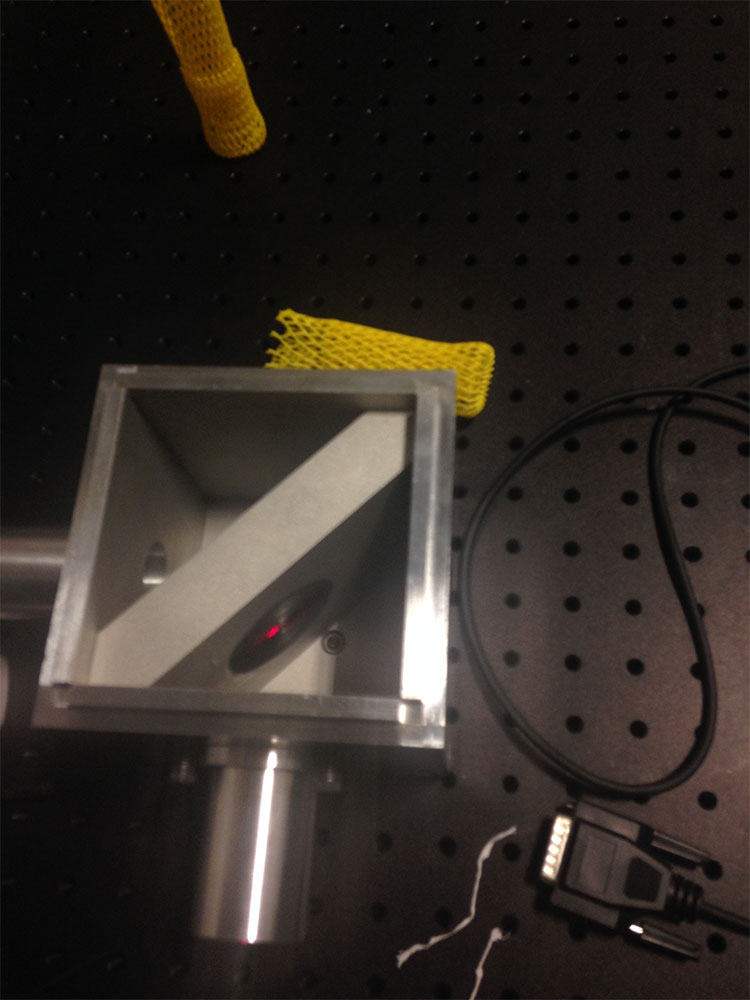

Laser Trap

Custom designed double beam laser trap. While dealing with lasers, it is necessary to be able to stop a beam safely, in this case two different beams can be safely trapped. The incoming beams are scattered upon impact with two ripple textured graphite targets. Large aluminum heat sinks convert the laser energy to safer waste heat.